If you have the misfortune of needing to replace an RLEC, you will get the RLECs ID from the diagnostic software. But you have to know where that ID is physically located in the pack. Here is a photo with all of the RLECs/modules labeled:

If you have the misfortune of needing to replace an RLEC, you will get the RLECs ID from the diagnostic software. But you have to know where that ID is physically located in the pack. Here is a photo with all of the RLECs/modules labeled:

Here is the response from Enerdel:

From: Battery Support <support@enerdel.com>

Date: Fri, Jun 17, 2016 at 7:22 AM

Subject: Inquiring on Think City Car

To: “john.mayer@greendropgarage.com” <john.mayer@greendropgarage.com>

Thank you for Inquiry.

We are sorry for your inconvenience, however, we no longer provide

replacement parts for the Think City Car.

Continue reading Trying to get in touch with Enerdel; UPDATE: Disappointing Success

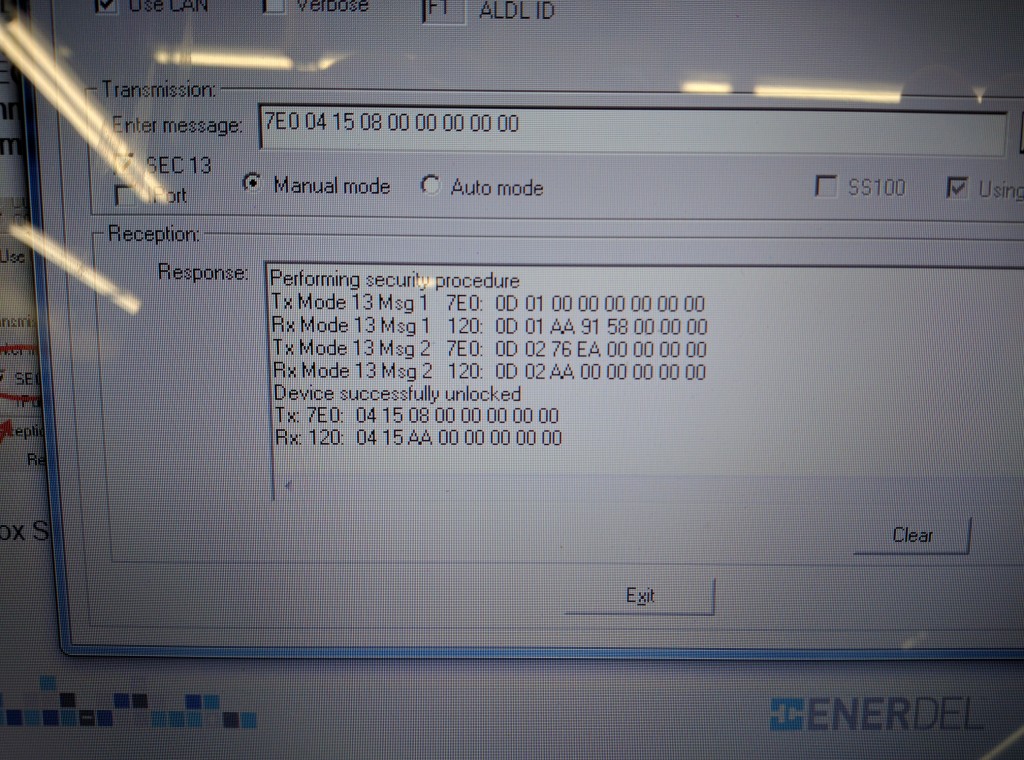

I have Enerdel’s ProgTool (specifically Programming Tool V4.16), which when configured properly I simply need to transmit a single message to the RLEC to set a new slave index/ID:

(For a description of the hardware required to connect to the RLEC, go to this post. You’ll need the PCAN adapter and the modified 4-wire RLEC wire harness.)

Enter message:

7E0 04 15 0X 00 00 00 00 00

Where X is the RLEC location ID ( 0-15 )

represented in hex ( 0-F )

But the ProgTool actually sends and receives a few messages (some kind of unlock procedure) before transmitting that message. Here’s a screen shot:

In the first sentence I glossed over the details of configuring the settings. Here’s what you need to do before you type in the transmission message:

Now replace the text in the “Enter message: ” text box with the message described above and click “Send.”

Now, when you install it into the pack make sure you put it in the correct position. Even Enerdel’s CommTool has inconsistent ways of referring to RLECs. Is the data that you’re looking at referring to the RLECs position in that pack by natural numbering (e.g. the first RLEC is number 1), or is it referring to the RLEC by its ID which is numbered in the way that is more conventional to computer programming (e.g. the first number is zero (aka 0, aka 0x0). It’s almost like they’re trying to trick you, so stay on your toes. Also it helps to know how they’re laid out in the pack.

Good luck!

It’s not the first time that we’ve seen this, but it’s probably the worst. The symptom of the car was that it would not start or charge, and one of the RLECs was reporting no cell voltage data. I had an RLEC on hand and programmed with the slave ID to replace the one that was not reporting data, but then I found this:

Continue reading Water in the traction battery

Continue reading Water in the traction battery

I’m not surprised anymore when a Think arrives at the shop and the rear liftgate is released. Often the latch position switch (that should turn on the “Door Ajar” light on the center console) is not adjusted correctly. And I’ve seen plenty of liftgate latches slowly get further and further out of adjustment until you really have to slam it to get it to shut. So here’s what you can do about it: Continue reading That Pesky Rear Liftgate Latch…

It has finally arrived! Or at least it is finally ready to be delivered!

The Think Traveling Diagnostic Kit is on its maiden voyage to southern California as of December 24, 2015. It will cost $150 per week plus shipping to rent the kit. Continue reading The Traveling Diagnostic Kit

Solar car

Soap box derby car

+STEAM outreach to high school (earlier?) students

Short TED talks at the beginning of meetings

Robo-kites

Deployable wind generators

Ship propulsion

Glider launches

Distributed suction cups

Configurable pulleys

Gravity and air flow cleaner

Vacuum crawler

Fog light protectors.

Gen 1 instrument panel visor.

HID headlight assembly cover remover.

I’ve heard that Midtronics has a version of what I want, but I’ve also heard that it costs around $2,000.

It’s pretty simple: Just a current probe that logs data for cars that we suspect a draw on. May as well have measure battery voltage, too.

I’m working on a Think today, so there are a lot of ideas floating around my head about things I could make to slightly improve these cars:

A shroud for the master cylinder to keep water from dripping on/standing on the brake fluid reservoir causing moisture contamination.

Maybe the same sort of shroud should be over the transaxle vent to prevent water intrusion…

A new cowl design that isn’t so crappy.

A silencer/muffler for the vacuum pump.

Headliner arch supports.

Rear fender liner stiffeners to prevent tire rubbing.

Rear hatch headliner baton.

Scan tool– Raspberry Pi + CAN adapter?