It’s not the first time that we’ve seen this, but it’s probably the worst. The symptom of the car was that it would not start or charge, and one of the RLECs was reporting no cell voltage data. I had an RLEC on hand and programmed with the slave ID to replace the one that was not reporting data, but then I found this:

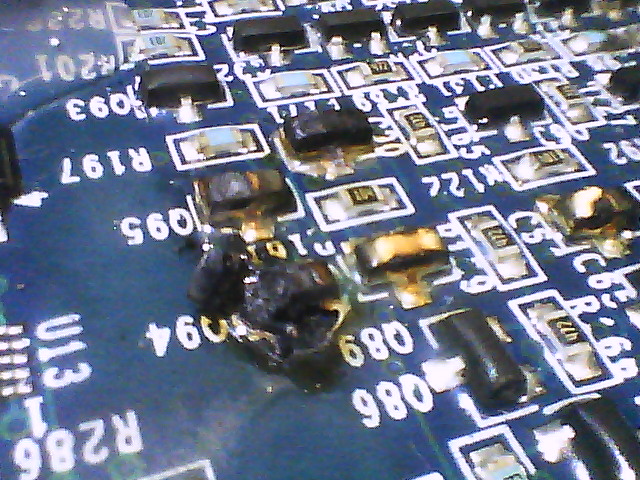

Here is the one component that I’m pretty sure is not going to come back to life:

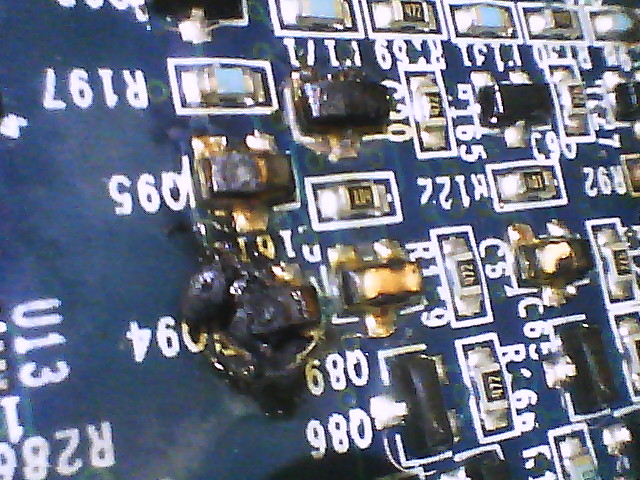

And here’s some of the blue crusty deposits/corrosion on the under-side of the boards:

It seems like it would be crazy to replace all of the RLECs, but I’m not sure that I would want to rely on them in their present condition.

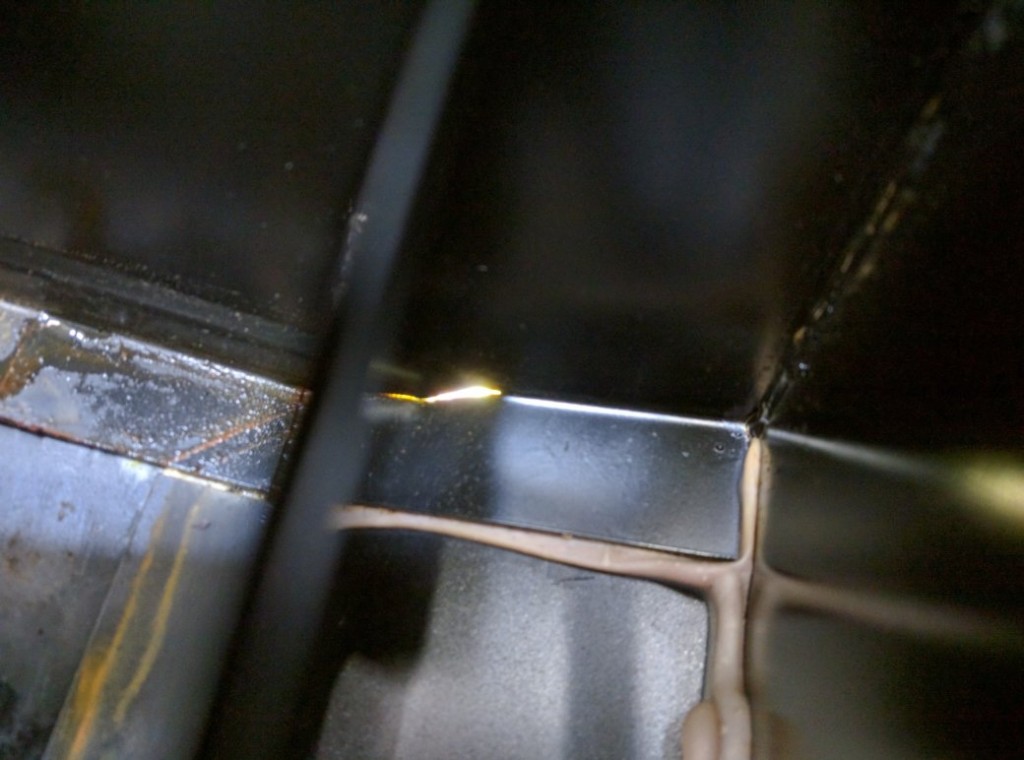

I’m considering developing a preventative maintenance procedure for the traction battery. It would involve drilling holes into the bottom of the battery case (with the battery still installed in the car). There’s plenty of room in between the battery modules below the contactors, fuses and current sensors, to drill without any risk of hitting the actual battery cells. I think I would test for leaks with smoke and air flow, apply RTV silicon to any suspicious locations around the flange and maybe apply a slight vacuum to try to pull the silicon into any cracks. And then I would stuff the free space inside the battery case with desiccant and seal it back up.

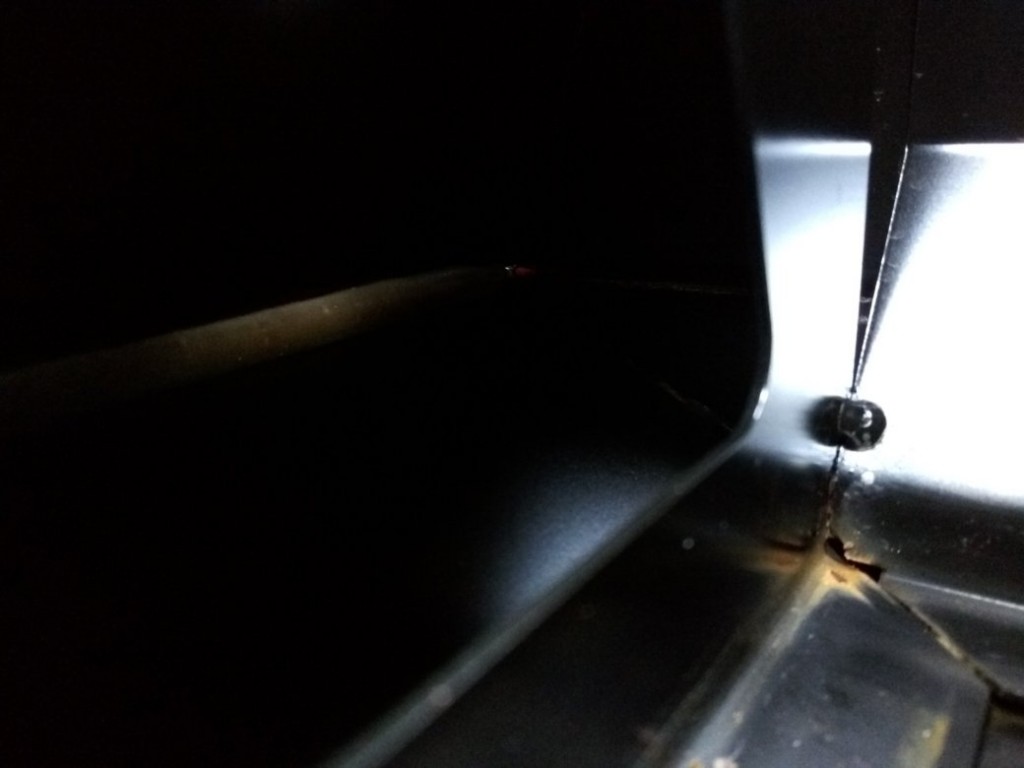

In the case above I found the leak to be just below the battery connector to the frame wires.